Heat treatment may be the most common process during manufacturing, but laser heating is currently only used in a few areas. Laser heat treatment requires low-brightness large-area uniform irradiation and precise control of heat; these requirements are quite complicated for traditional high-power lasers, while VCSEL arrays are inherently equipped with these capabilities and are easy to operate.

Due to fast response capability and low power consumption, Vertical Cavity Surface Emitting Laser Diodes (VCSELs) have been widely used in data communication and sensing applications. By integrating large-area VCSEL array, power density of several W/mm2 can be achieved. These characteristics enable VCSEL to enter the high-power application field and become an ideal heating application solution, such as melting, welding, curing, drying, sintering, etc.

Traditional industrial heating, including burners, convection ovens, hot air blowers, microwave ovens, induction heating, halogen lamps, etc., these methods have their specific advantages and continue to play a role in certain fields. However, they are large in size, start and heat slowly, and heat control is not precise.

Compared with traditional radiant heat sources, edge-emitting lasers and pumped solid-state lasers have higher brightness, but for heating applications, they maybe with too high-power density and too small irradiation area. Through special optical design, homogenization and expansion of the beam, a larger area can be uniformly irradiated, but a complex optical lens combination is required, which makes the system bulky, fragile, and expensive.

Just as LEDs are now replacing incandescent lamps and general lighting lamps, VCSELs will also become the next generation of heating lamps due to significantly improved efficiency and reliability. In terms of manufacturing and integrated packaging processes, VCSEL as a heat source and LED as a light source have many similarities, and both have cost advantages.

Without any special optical design, VCSEL can provide very uniform illumination and can be scaled to an area of any size. VCSEL does not require fiber coupling system or scanner systems, is very compact, and can precisely control heat. At the same time, the narrow bandwidth characteristics allow VCSEL to match the specific absorption spectrum of material processing. The inherent reliability of VCSEL and the packaging compatible with LEDs provide the system with high reliability and the ability to work in harsh environments.

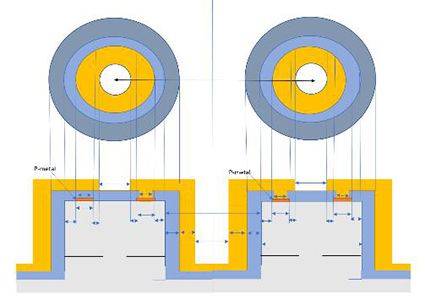

Depending on wavelength, mesa and aperture size, optical output power of each emitter of VCSEL ranges from 1 to 20 mW. Densely arranged VCSEL array can achieve higher output power.

|

Figure 1: Cross-section of VCSEL aperture.

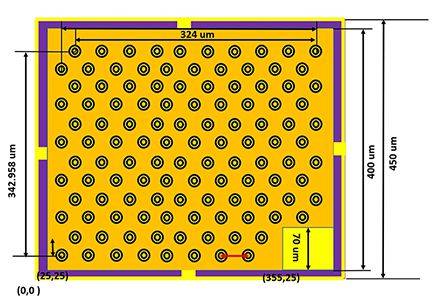

|

Figure 2: VCSEL array

|

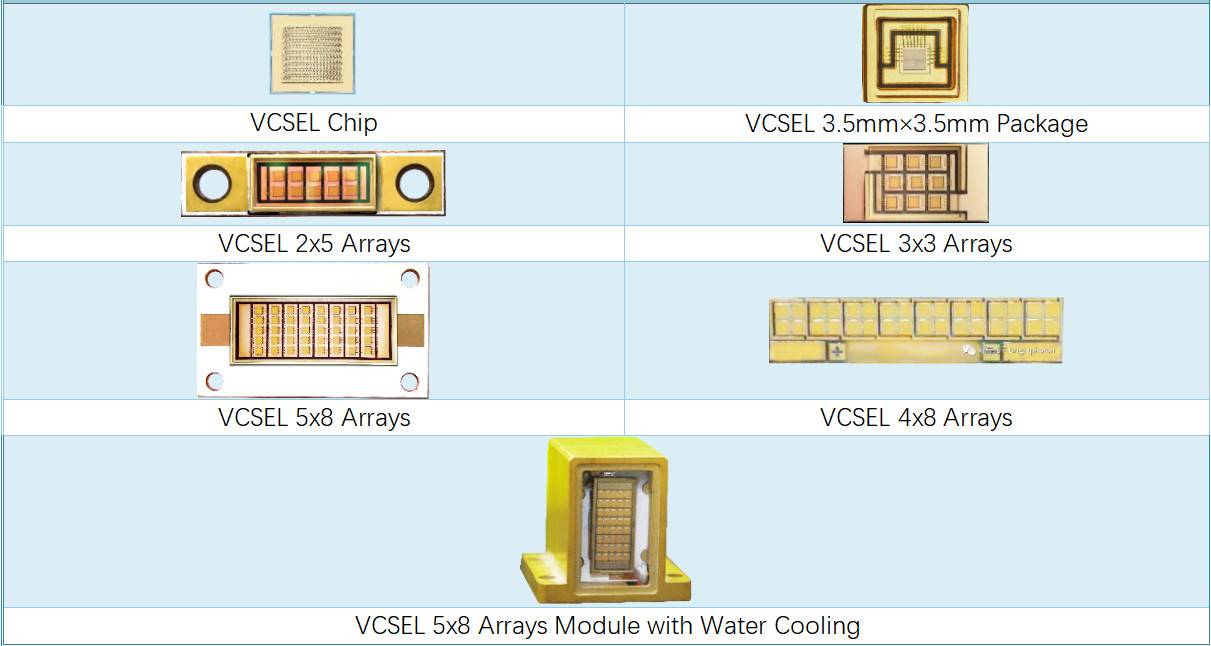

A more powerful chip array can be formed by integrating multiple chips. Brightlaser’s 2D array VCSEL module includes multiple independent chips with power conversion efficiency of over 50%, providing continuous (CW) power from tens of watts to 10kW or greater quasi-continuous (QCW) power, covering wavelengths of 808nm, 850nm and 940nm, users can choose different wavelengths according to different materials to be heated. The VCSEL 5x8 Arrays module shown in below table contains 40 chips of 1.5 X 1.5 mm2. The chips are soldered on a ceramic substrate with high thermal conductivity, and then the submount is soldered on a copper base for heat dissipation. Forty chips are connected by a circuit in series and in parallel, and the anode pad on the chip is wire-bonded to the pad of the next chip. The two ends of the substrate are Anode and Cathode, which are used to connect to the power supply. This VCSEL module is only 25 X 11 mm2 and can provide a total continuous output power (CW) of more than 300 W.

Brightlaser High Power VCSEL Assembly

Users can make any combination according to diversified needs. For example, by stacking the modules in a two-dimensional mode, total output power can easily be multiplied. Moreover, VCSEL heating system can be changed spatial heating distribution by individually controlling different segments of VCSEL chip emission zones. The new heating patterns can be dynamically realized during the operation and be enhanced the level of process flexibility.

Due to its unparalleled superior characteristics, VCSEL array has extended the application of traditional high-power lasers to the industrial heating field, like 3D printing material curing, metal forging, plastic welding, ink drying, etc. Undoubtedly, high quality benefits and low cost are the decisive key factors.

Brightlaser provides various standard laser modules with high cost-efficiency. According to specific requirements, Brightlaser is able to supply various powers, wavelengths , addressable, customized solutions.

Feedback from some customers:

"We actually did some characterization of your chip and got 330W of output power at short pulses (~250 us), which is good. We also characterized the wavelength non-uniformity between chips and found it to be quite average."

"I'm really happy to see the quality of the assembly of this array, which is definitely the kind of precision we need."

Innovations for Freedom

Brightlaser was founded in 2014, is a global pioneer supplier in VCSEL technology from components, sensors, to total solutions for AI/IoT applications including Optical Communication, Consumer Electronics, ADAS, Machine Vision, Telecom, Robotics, Smart House, Surveillance System, etc.

As a high-tech company, Brightlaser possesses its own VCSEL intellectual properties in wafer design, advanced chip process, and applications. Brightlaser headquartered in Hong Kong, established branch offices in Shen Zhen and Zhong Shan of China. The factory located in Zhong Shan covers footprint of 160,000 Sq. ft., equipped with globally state- of-art GaAs techniques, and the first 6-inch VCSEL chip fab & packaging line in mainland China.

In recent years, Brightlaser has caught up extremely quickly with all the opportunities the market has been giving, is becoming increasingly competitive. Currently, we are working with world-wide-leading partners and customers in technologies, marketing, and sales.

To cope with the rapidly growing, we are seeking professional dealers, distributors to join this promising field. As a self-driven, proactive, taking initiative, team player, you are welcome to our fast-paced, dynamic team of collaborators.