In recent years, the market demand for laser processing has increased due to its inherent advantages and technological development. Diode-pumped solid-state (DPSS) laser has widely drawn market attention due to its narrow pulse widths, high output energy, high peak power, and good material absorption. Take the industrial field as an example, in addition to traditional laser marking, scribing, cutting, drilling, material removal, surface treatment and special material processing applications, the development of new technologies such as additive manufacturing, 3D printing, new display, UV laser marking, etc., further expand the application of solid-state laser.

Figure 1: Laser Process

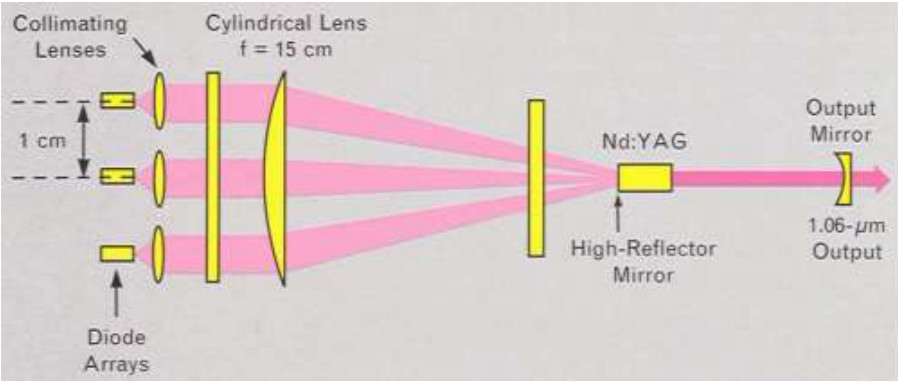

The 808nm wavelength infrared AlGaAs laser diode is the core component to pump a Nd:YAG or Nd:YVO4 crystal which produces 1064nm wavelength laser. High-energy pulsed DPSS lasers are typically pumped by high-brightness stacks of EEL (Edge Emitting Laser) bars. Recently, pump modules comprising high power 2D VCSEL arrays have emerged as attractive alternatives to pump DPSS lasers. For DPSS lasers, the coupling of light is very important. There are two kinds of coupling, spatial coupling, and fiber coupling. For spatial coupling, the pump source and the substrate can be separated to reduce the production costs and complexity of manufacturing process. For fiber coupling, a fusion splicer is required for welding of optical fibers, which increases manufacturing costs.

Figure 2: The composition of semiconductor-pumped solid-state lasers

Compared with the traditional 808nm EEL pump source, VCSEL has better wavelength stability, the wavelength temperature coefficient is 0.07nm/deg or less while that of EEL is 0.25-0.3nm/deg. Besides, VCSEL has the characteristics of smaller divergence and circular spot, which is beneficial for collimation or focusing and simplifies the coupling link, it also helps to reduce costs and improve reliability. EEL suffer from catastrophic optical damage (COD) at the facets, a common problem causes reducing reliability in laser diodes. VCSELs do not show this damage as the end facets are designed differently. Moreover, VCSEL has the advantages of high reliability, wide operating temperature range, and can better meet industrial requirements of lasers.

|

Feature |

VCSEL |

EEL |

|

Beam quality |

Best, round, low divergence |

Fair, ellipse, asymmetric |

|

Temperature stability |

0.07nm/deg |

0.25-0.3nm/deg |

|

Spectral width |

1nm |

1-2nm |

|

Speckle |

Low in an array |

High |

|

Cost |

Low-Medium |

Medium-High |

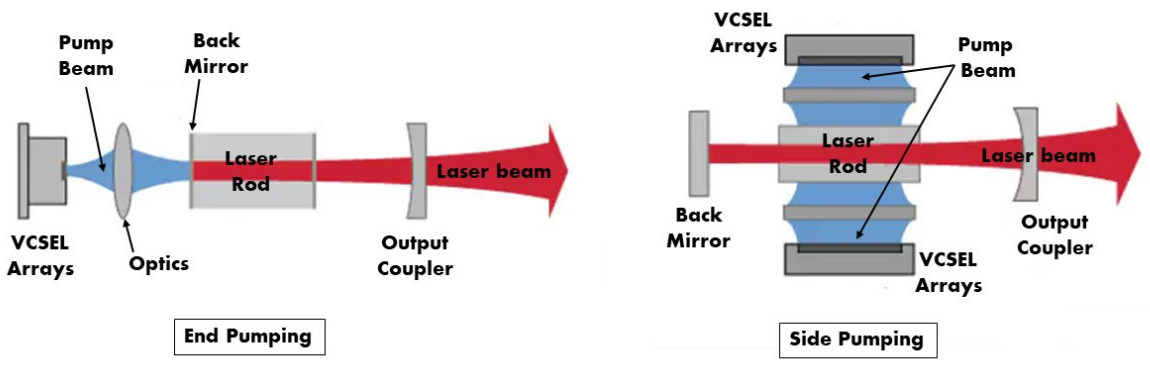

High power 2D VCSEL arrays are well suited for side-pumped and end-pumped solid-state lasers such as actively and passively Q-switched Nd:YAG lasers. VCSEL arrays can be arranged in a layout that is optimal for uniform illumination of the gain medium to achieve good beam quality and high energy extraction resulting in a high single-pass absorption. They are well suited for constructing very compact side-pumped solid-state lasers. Furthermore, the chip size and the position of each emitter within an array can be photolithographically defined. The VCSEL array chip can be formed as square or rectangular shape and the emission area within the chip can be of any shape. They are well suited for end-pumped solid-state lasers.

Figure 3: VCSEL Arrays in Laser Pump Source

In response to the requirements of high pulse energy and small volume solid-state laser pump source, Brightlaser has developed 808nm high-power and high-energy density VCSEL lasers for end-pump and side-pump. The high efficiency device based on Brightlaser 808nm VCSEL arrays is compact, good wavelength stability and consistency, narrow line width, good circular spot beam quality. Brightlaser’s 808nm VCSELs are suitable for spatial coupling type of 808nm high power DPSS lasers, and energy density can reach up to 770W/cm². it can be used for many industrial, medical, and other applications.

Brightlaser’s 808nm VCSEL series

Demonstrate a variety of high power, high efficiency and high beam quality 808nm VCSEL arrays. |

VCSEL Chip |

VCSEL 3.5mm´3.5mm Package |

VCSEL 2x5 Arrays |

VCSEL 3x3 Arrays |

VCSEL 5x8 Arrays |

VCSEL 4x8 Arrays |

VCSEL 5x8 Arrays Module with Water Cooling |

Brightlaser can also provide product customization services, such as vertical stacking of multiple laser array bars to form a high-power laser output. High-density laser array bar stacking technology is used with bar spacing being small to enable the module to obtain high-brightness laser output while maintaining a small size and high efficiency.

Innovations for Freedom

Brightlaser was founded in 2014, is a global pioneer supplier in VCSEL technology from components, sensors, to total solutions for AI/IoT applications including Optical Communication, Consumer Electronics, ADAS, Machine Vision, Telecom, Robotics, Smart House, Surveillance System, etc.

As a high-tech company, Brightlaser possesses its own VCSEL intellectual properties in wafer design, advanced chip process, and applications. Brightlaser headquartered in Hong Kong, established branch offices in Shen Zhen and Zhong Shan of China. The factory located in Zhong Shan covers footprint of 160,000 Sq. ft., equipped with globally state- of-art GaAs techniques, and the first 6-inch VCSEL chip fab & packaging line in mainland China.

In recent years, Brightlaser has caught up extremely quickly with all the opportunities the market has been giving, is becoming increasingly competitive. Currently, we are working with world-wide-leading partners and customers in technologies, marketing, and sales.

To cope with the rapidly growing, we are seeking professional dealers, distributors to join this promising field. As a self-driven, proactive, taking initiative, team player, you are welcome to our fast-paced, dynamic team of collaborators.